The Ford Rouge plant my great-grandfather toiled in in the early 20th century was a tough, dangerous, dirty place. There’s a reason the Rouge was one of the founding sites of the American labor movement: Workers organized because they were desperate for safety protections as well as job security.

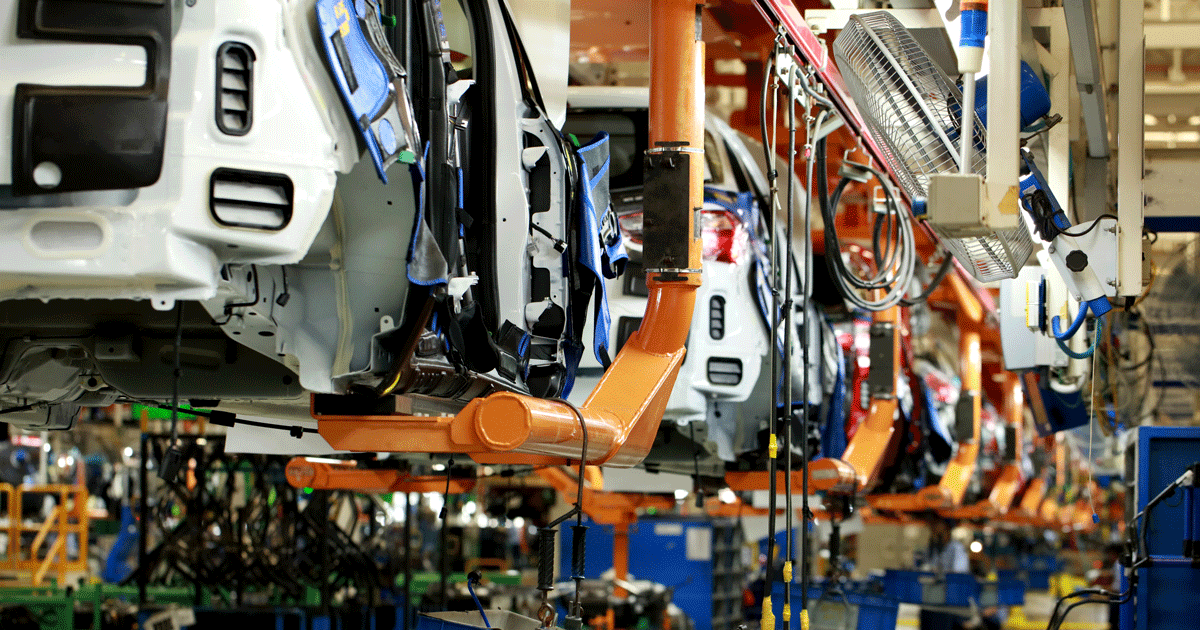

Today, the Rouge looks and operates nothing like the 100,000-employee industrial city it was at its 1930s peak. It’s clean and safe and it also has about 93,000 fewer employees, with many jobs that were once done by humans handled by robots.

Alabama is quickly becoming a booming center for human auto employment, with suppliers attracted to both the state’s strong anti-union policies and low-wage workers. Instead of the comfortable living that the manufacturing jobs of yore provided, Alabama’s auto plants offer poorly-trained workers low wages in work environments where they often risk life and limb. An absolutely bone-chilling recent Bloomberg News article describes an Alabama auto industry that prioritizes productivity over safety with tragic results.

The piece tells the tragic story of 20-year-old Regina Elsea, who was crushed by a robot she was attempting to fix at a plant operated by supplier Ajin USA. Workers at plants like Ajin’s have complained that made Alabama-based auto suppliers skimp on training and safety and push workers to superhuman productivity levels.

Not only are many jobs in Alabama auto suppliers seemingly less safe, they are certainly less lucrative. Alabama auto wages tend to hover around the minimum wage. And while President Donald Trump staked much of his economic agenda on the idea that he would boost jobs in America’s manufacturing sector by making it more difficult for companies to go off shore, Trump is clearly not a big fan of high wages for auto workers. In a 2015 Detroit News interview, Trump predicted that automakers could convince Michigan auto workers to work for less by leveraging the threat of moving jobs to low wage states.

Michigan Future Inc. has consistently argued that it’s time for political leaders on both sides of the aisle to recognize that Michigan’s 1950s manufacturing-based economy is not coming back. Manufacturing jobs account for less than 10 percent of the nation’s workforce. Even if by some miracle Donald Trump brought every offshore manufacturing job back to the United States, the jobs will likely look more like Alabama than Michigan.

If Michigan wants to join states like California, Massachusetts and Minnesota that have thriving 21st Century economies, we need to increase the number of our citizens who have four-year degrees. As my colleague Lou Glazer has pointed out, it’s no coincidence that Michigan ranks 32nd for both four-year degree attainment and per capita income. There is ample evidence that when making decisions about where to set up shop, 21st Century employers are laser focused on talent.

Instead of ignoring that reality and pining for the past, it would be smart for us to invest in improving Michigan’s K-12 and higher education outcomes so Michigan workers are able to compete for jobs that are safe and pay decent wages.